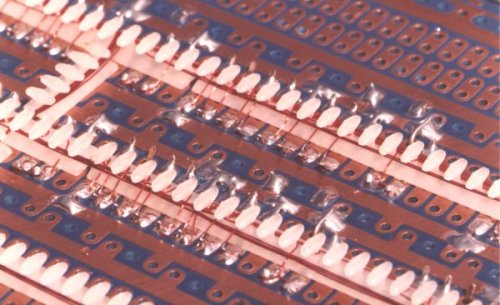

This picture shows the board after the soldering has been done.

This operation requires some skill. The correct size bit should be used at a reasonable temperature.

A Weller temperature controlled iron is recommended with a grade 7 bit. The size/shape below the standard bit has been found ideal in the past.

Having too cool an iron is not a good idea as the work takes longer allowing heat to travel up the wire cutting it into the plastic comb. It is essential to melt the insulation of the wire quickly therefore the right bit size and temperature is important.

Careful inspection, with a watchmakers eyeglass, is worthwhile at this stage looking for poor joints. Look for insulation that has not been properly dissolved also connections that have been missed.